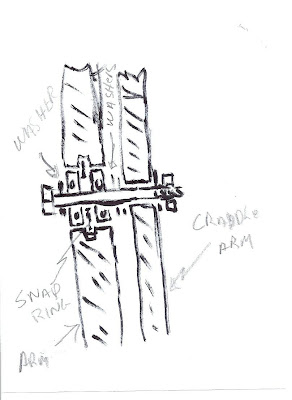

Hi Fab. This plan would require the addition of a bearing retainer to prevent the "arm" from slipping against the bearings and hitting the "cradle arm." This would mean making the pocket deeper which would leave the bottom of the pocket very thin. For this reason I recommend a single bearing with retainer as in the drawing I posted on the first page of this thread. Since skate bearings are designed for millions of revolutions under much greater axial and radial loads than they will be subjected to in a scanner, I think a single bearing for each joint is more than sufficient. Cheers.Fab52 wrote:Hi jck,

I was looking at my autocad and I think I found an other way to skin this cat how about this one.

This is the easiest way I think. A deeper pocket in the arm and some washer will do the job.

See you

Fab

Daniel's Work Thread: Toward a Hackerspace Scanner

Moderator: peterZ

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Since we're all posting drawings, this is what I was referring to earlier.

If you're going to use a single bearing, it should be on the outside of the two arms to offer the most support of an radial load. In the drawing below the two bearings are captured by the through bolt, however if the fit of the bearing into the arm is sloppy, the arms could move off of the bearings, toward the center, and rub against each other. Jck47's screws would prevent this from being a problem, however a tight fit of the bearing into the arm should prevent this from happening, since there aren't axial forces at play with the movement of the arms.

If you're going to use a single bearing, it should be on the outside of the two arms to offer the most support of an radial load. In the drawing below the two bearings are captured by the through bolt, however if the fit of the bearing into the arm is sloppy, the arms could move off of the bearings, toward the center, and rub against each other. Jck47's screws would prevent this from being a problem, however a tight fit of the bearing into the arm should prevent this from happening, since there aren't axial forces at play with the movement of the arms.

- rob

- Posts: 773

- Joined: 03 Jun 2009, 13:50

- E-book readers owned: iRex iLiad, Kindle 2

- Number of books owned: 4000

- Country: United States

- Location: Maryland, United States

- Contact:

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Oh. Right...jck57 wrote:This plan would require the addition of a bearing retainer to prevent the "arm" from slipping against the bearings and hitting the "cradle arm."

The Singularity is Near. ~ http://halfbakedmaker.org ~ Follow me as I build the world's first all-mechanical steam-powered computer.

- rob

- Posts: 773

- Joined: 03 Jun 2009, 13:50

- E-book readers owned: iRex iLiad, Kindle 2

- Number of books owned: 4000

- Country: United States

- Location: Maryland, United States

- Contact:

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

I'd be worried about someone just pulling at the pieces and moving them out of alignment. There's your unintended axial force! I think jck47's idea has a lot of merit.dpc wrote:Jck47's screws would prevent this from being a problem, however a tight fit of the bearing into the arm should prevent this from happening, since there aren't axial forces at play with the movement of the arms.

The Singularity is Near. ~ http://halfbakedmaker.org ~ Follow me as I build the world's first all-mechanical steam-powered computer.

-

Fab52

- Posts: 63

- Joined: 21 Feb 2012, 21:10

- Number of books owned: 0

- Country: Canada

- Location: Montreal South Shore, Quebec, Canada

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Hi guys,

So we're all brainstorming today !!!

Jck, you're right for the first cad I post this morning ... I will need trust bearing to make it work. Ok this one go in file 13.

The second one will work if the fit for the bearing are not sloppy ... If they are, you will need some sort of retainer, the two small screw is a good idea or locktite....

See you.....

Fab

So we're all brainstorming today !!!

Jck, you're right for the first cad I post this morning ... I will need trust bearing to make it work. Ok this one go in file 13.

The second one will work if the fit for the bearing are not sloppy ... If they are, you will need some sort of retainer, the two small screw is a good idea or locktite....

See you.....

Fab

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Ah yes, the dreaded "user" that does things you never intended. I should know better from my work as a software engineer.rob wrote:I'd be worried about someone just pulling at the pieces and moving them out of alignment. There's your unintended axial force! I think jck47's idea has a lot of merit.

Jkc47's method would certainly prevent that from happening and it would also have the added bonus that it anchors the bearing to what may be a sloppy counter bore (getting a nice press fit into a plywood c'bore is a bit optimistic). You might even get away with only needing a single screw per bearing. I've seen this technique used before where just the screw head held the bearing edge (no washer), but that was in an aluminum counter bore. You could also just epoxy the bearing into the plywood counter bore, I suppose. It would be unlikely that those bearings would ever wear out during the lifetime of the scanner and need to be removed.

BTW, the scanner that I'm currently designing doesn't use any arms or bearings to lift the cradle. Due to the nature of the self-leveling cradle and large book sizes that I plan to support, it needs more horizontal movement/clearance and the book support panels would hit the Hackerspace scanner's side arms and linkage. I'm planning to use pulleys and cable that leave the sides of the scanner completely open for the cradle to move into that area. The cable is fastened to a horizontal lifting bar across the front that slides up and down tracks mounted on the two front posts. That's the current thinking, anyway. This thing has changed design so many times as I think of ways to improve it, so that might not be what I end up with in the end.

-

Fab52

- Posts: 63

- Joined: 21 Feb 2012, 21:10

- Number of books owned: 0

- Country: Canada

- Location: Montreal South Shore, Quebec, Canada

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Hi guys,

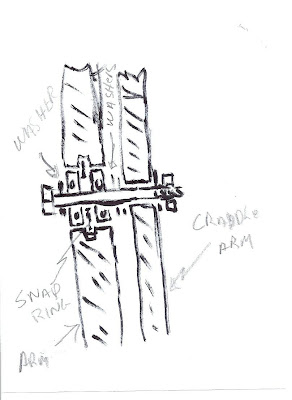

Ok, here's how I will do it as machinist, in steel or alu with a minimum axial load, this is what we are doing, (your bearing hubs for the cutters under your John Deere lawn mower are done this way) but I don't know if you can do that with your CNC router.

Here's the design from the cad I was born with:

Tell me guys are you able to do a snap ring groove with your CNC router ? Or is it a pain in the ASK for you ????

If it is a pain we can go with the retainer proposed here by jck.

See you

Fab

P.S. G'wiz, looking at my drawing I notice there is a little wind from the south tonight, without that wind my drawing will be perfectly strait....

Ok, here's how I will do it as machinist, in steel or alu with a minimum axial load, this is what we are doing, (your bearing hubs for the cutters under your John Deere lawn mower are done this way) but I don't know if you can do that with your CNC router.

Here's the design from the cad I was born with:

Tell me guys are you able to do a snap ring groove with your CNC router ? Or is it a pain in the ASK for you ????

If it is a pain we can go with the retainer proposed here by jck.

See you

Fab

P.S. G'wiz, looking at my drawing I notice there is a little wind from the south tonight, without that wind my drawing will be perfectly strait....

- rob

- Posts: 773

- Joined: 03 Jun 2009, 13:50

- E-book readers owned: iRex iLiad, Kindle 2

- Number of books owned: 4000

- Country: United States

- Location: Maryland, United States

- Contact:

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

It's definitely an anal pain! You would need a special router bit to cut those internal grooves, and that means changing the bit and re-zeroing the CNC router just to cut those grooves, which takes time. It's not impossible, but almost nobody will want to do it!Fab52 wrote:Tell me guys are you able to do a snap ring groove with your CNC router ? Or is it a pain in the ASK for you ????

The Singularity is Near. ~ http://halfbakedmaker.org ~ Follow me as I build the world's first all-mechanical steam-powered computer.

- rob

- Posts: 773

- Joined: 03 Jun 2009, 13:50

- E-book readers owned: iRex iLiad, Kindle 2

- Number of books owned: 4000

- Country: United States

- Location: Maryland, United States

- Contact:

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

What size books are you going to scan? I'd like to know because eventually we're going to want different sized Hackerspace Scanners.dpc wrote:Due to the nature of the self-leveling cradle and large book sizes that I plan to support, it needs more horizontal movement/clearance and the book support panels would hit the Hackerspace scanner's side arms and linkage.

Also, this was supposed to be Dan's work thread... but any thread on here tends to devolve into an engineering discussion!

The Singularity is Near. ~ http://halfbakedmaker.org ~ Follow me as I build the world's first all-mechanical steam-powered computer.

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

I've got a few coffee table books around here and some atlases that I'd like to be able to scan. Nothing too large, it's just that the self-leveling mechanism that I've come up with requires that the book support panels slide up and down, and when they go up, they also go out and that can affect the max book thickness you can scan. I could just increase the entire width of the scanner base, but why require all that space when you only need it for certain books? It's also a fun engineering problem to solve.rob wrote: What size books are you going to scan? I'd like to know because eventually we're going to want different sized Hackerspace Scanners.

Also, this was supposed to be Dan's work thread... but any thread on here tends to devolve into an engineering discussion!

OK, so back on topic...

Dan, if I were going to cut arms for 50 scanners, I'd be cutting the counter bores in one side (the outside) of each arm, epoxying the bearings into the arms, then put a single spacer between the two arms that contacts the inner bearing races (similar to my drawing above, but only use a single "tube" spacer). You'll need a through-hole large enough to ensure that the spacer doesn't rub on the arm. The spacer length is chosen to keep the arms about 1mm apart so they don't rub against each other.

Jck57's method of anchoring the bearing to the counter bore is superior to the epoxy since you can replace the bearing much easier, but that's a lot of holes to drill for a scanner that would likely never wear out a bearing. If the epoxy eventually gave way and allowed the arm to move inward and rub, you could always retrofit in situ to Jck57's method since the bearings are on the outside of each arm.