Page 6 of 22

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 04 Mar 2012, 22:20

by daniel_reetz

...or another possibility would be to cut the first two passes with a higher deflection value, and then cut the last pass as a "beauty pass" but I think I'd rather keep an even strain on the machine rather than loading it differently at different times.

For reference, here is

the list of bits that TechShop stocks for their ShopBot (a CNC router comparable to my router)

And here is the

LMT Onsrud catalog in PDF (I've been using their bits and have had good luck with them; this catalog specifies which bit for which type of wood)

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 05 Mar 2012, 02:20

by daniel_reetz

daniel_reetz wrote:

With that in mind, I spent the morning evaluating DIY Hall Effect homing switches. In particular, I copied the electronic design in

this post. Unfortunately I burned up the single hall effect sensor I had laying around (an Allegro 02E). Instead of wasting more time on this, I simply ordered

these nice, prebuilt sensors from DigiKey. Sadly, with DigiKey the shipping costs almost as much as the parts themselves. I expect them to arrive mid-week.

I will be able to install those sensors on X and Y axes, and use a

touch plate for the Z axis. With that kind of setup, the machine will be able to be set up with fixtures drilled into the bed, so I can easily position plywood in a repeatable fashion.

As a reference for myself, here is

a good writeup on making a touchplate work with Mach3. Here is a

CNCZone thread on the topic.

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 05 Mar 2012, 12:56

by rob

So I didn't know that about HSS versus carbide. The Onsrud cutters I use are carbide, so I never really had to care

Cutting depth = diameter is pretty standard.

So you got 180 ipm, or 3 ips. Since this is at 7500 rpm, and you want 12000 rpm, just increase your feed rate proportionally. 180 x (12000/7500) = 288 ipm, or 4.8 ips. Personally, I would be

scared to run at this speed, which is much faster the speed I run (3.6 ips), and results in a higher chip load than Onsrud recommends. But, hey, the worst you can do is break the bit or push the workpieces around.

"There are no experimental failures. There's only more data." -- Bryce Lynch,

Deities (season 2 episode 2), the TV Series "Max Headroom" (1987)

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 05 Mar 2012, 15:21

by daniel_reetz

I've also been using carbide, at least the last few bits.

I'm not that worried about running at that speed - only because it will take some pretty seriously smart programming to get there. I've got some example sheets laid out with many of the same parts grouped together, and I think on those I could come close for short periods of time.

At this moment, I am thinking it would be great if I could cut, say, ten of these in one Saturday afternoon. I don't want to be working on this every day of the week like I am now. One afternoon of cutting and packing should be good. So grouping things up and getting the cut rate as high as possible seem like the right things to be working on.

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 14:30

by jck57

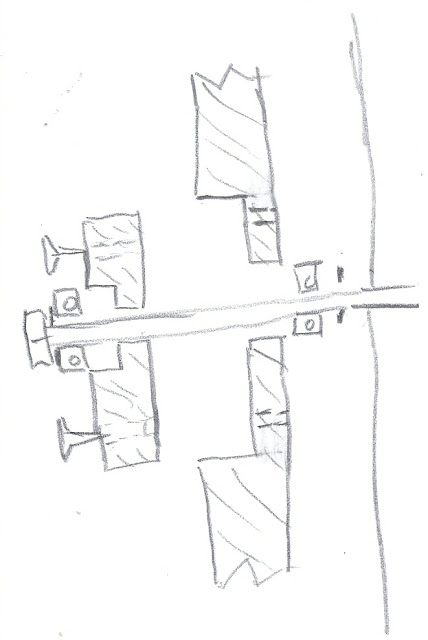

Fab52 wrote:Hi,

Well if you want to keep the baltic birch finish on both side you can go with this... but you will have to cut three pieces for each arm .

Here's the autocad:

I hope this give you some idea....

Thanks for the great works

Fab

Here's a similar scheme:

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 16:27

by jck57

daniel_reetz wrote:

Wow, so roughly 47% of the wood ends up as waste in the current sheet model. Given how sloppy I was with the coloring, that could be +/-5%, but it's still substantial waste. Fine for one-offs, I think, but maybe not as fine for when I go into production mode.

It looks like many of the pieces could be laid out exactly 1/4" away from each other, thus saving wood, cutting time, and cutter wear. But maybe there's some other reason to avoid this type of layout.

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 18:30

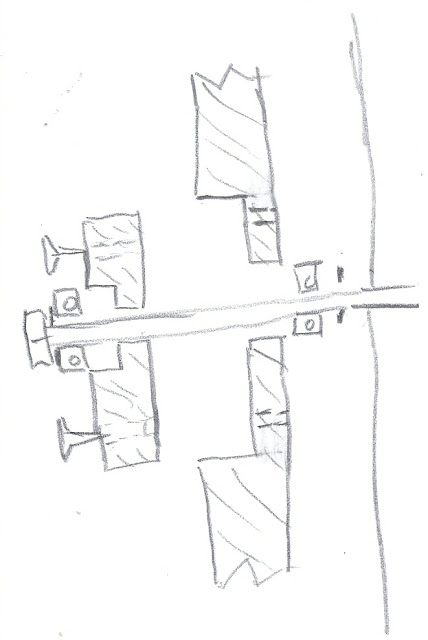

by Fab52

Hi jck,

Hey, this is the best solution I've seen so far.

Congratulation

This should'nt be hard to do with your CNC Daniel and Rob ???

Amazing we can even keep the two bearings design...

Here's from my cad:

I don't think there is a need to keep the original two bearings design if we are able to put the one bearing design in the center of the arm thickness.

Again great design, I hope the master mind behind this book scanner will like it.....

Keep the good work

Fab

You know you're old when everything you know is absolete... So keep learning if you want to stay young !!!

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 21:15

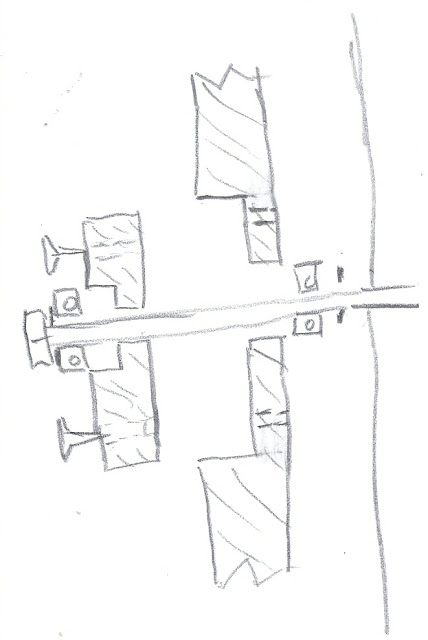

by jck57

Fab52 wrote:Hi jck,

Hey, this is the best solution I've seen so far.

Congratulation

This should'nt be hard to do with your CNC Daniel and Rob ???

Amazing we can even keep the two bearings design...

Here's from my cad:

I don't think there is a need to keep the original two bearings design if we are able to put the one bearing design in the center of the arm thickness.

Again great design, I hope the master mind behind this book scanner will like it.....

Keep the good work

Fab

You know you're old when everything you know is absolete... So keep learning if you want to stay young !!!

Well done, mon ami. This will totally work if they want two bearings.

Cheers.

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 21:22

by Fab52

Hi jck,

Let's wait for their comments.... but I think we do a nice brainstorming to find a solution to the flipping sheet problem....

You find the solution but I was not far behind...

breathing down your neck ????

See you

Fab

Re: Daniel's Work Thread: Toward a Hackerspace Scanner

Posted: 07 Mar 2012, 23:08

by rob

Well, so far I've cut one scanner using the one bearing solution, the one where it's just a press fit and you use nuts as spacers. I'm going to be doing some more in the following weeks. If I hear that there's a problem, we can start looking at these other solutions. There's certainly many to choose from!